Minimox should be used in high temperature, aggressive environments where stainless steel oxidation prevention is tantamount to improving profitability. Minimox treatment forms a thin, dense, adherent oxide that reduces scale formation and acts as a diffusion barrier, decreasing corrosion.

Metals Manufacturing & Heat Treating

Metals heat treating presents challenging environments for not only the parts that are being treated, but also for the furnaces, belts, curtains and fixtures used in the process. Heat treatment is often performed in controlled atmospheres to prevent surface scaling, carburization or decarburization. With Minimox Self-Protective Alloy Treatment, many chromia- and alumina-forming alloys can be heat treated in air rather than in vacuum. The lifetime of furnace components, like thermocouple covers and belts, can be extended.

Gas & Oil Processing

Minimox was developed to reduce material flaking at high temperatures. Alloys with adherent surface oxides, like the oxides generated by Minimox, will reduce coking. In contrast, alloys not treated with Minimox will exhibit cracking oxides that enhance coke deposits. In another application, metal dusting is a severe form of corrosion that manifests itself as a break-up of bulk metal to metal powder in the presence of specific types of carbon-rich atmospheres, including petroleum plants. Alloy treatment & oxidation with Minimox reduces metal dusting when compared to untreated alloys.

Chemical & Materials Development

In addition to oxidation and corrosion protection, a wide range of materials systems can improve their properties with Minimox Self-Protective Alloy Treatment. Coating of composite fillers with solutions like Minimox (before infiltration) have yielded improved mechanical properties of magnesium-, aluminum- and polymer- based composites. Minimox treatment and thermal processing can alter catalytic properties of surfaces.

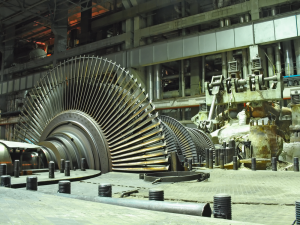

Power Generation

Reduction of material flaking in turbine systems can reduce particle erosion efficiency losses. Solid oxide fuel cells require dense, adherent stainless steel coatings to reduce the oxidation rate at the elevated temperatures seen in service. Treating stainless steel with Minimox and modifiying the oxidation temperature allows for some customization of the thermal oxide chemistry to reduce spalling and improve the thermal expansion mismatches in these systems.

Aerospace

A range of light-weight materials can be successfully treated, including aluminum, titanium, and magnesium alloys. Structures with complicated geometry like honeycombs can be coated to improve their corrosion and oxidation resistance.