Stainless Steel Oxidation Resistance

The Minimox® coating process was initially developed to reduce material loss due to excessive oxidation. A significant amount of data is available for a wide variety of alloys, including martensitic, ferritic, austenitic and duplex stainless steels, under a wide variety of temperatures and conditions. Please contact our office if you have questions about a specific alloy.

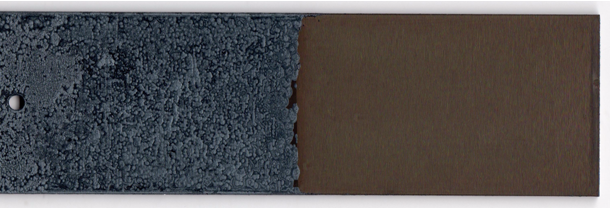

410 stainless steel. Recommended maximum service temperature for continuous exposure in air = 620°C (1150°F). Partially treated sample below was heated to 850°C for 30 hours.

Left: Untreated and oxidized 410 stainless. Thermal oxide is thick, flaking Fe2O3.

Right: Minimox-treated and oxidized 410 stainless. Thermal oxide is thin, adherent Cr2O3 + Cr-Mn-O spinel, even though there is no Cr or Mn in the solution.

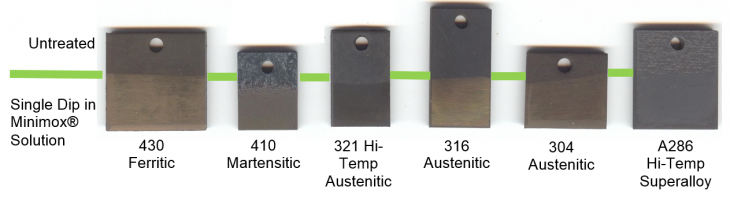

As an example of the versatility of this process, an assortment of alloys was partially coated with a single dip in Minimox® solution and heated to 850°C for 24 hours in air. The results are illustrated in the figure below.

All of these coupons were partially dipped in Minimox® solution a single time and heated to 850°C (1560°F). Protection is afforded to all of these alloys.

Nickel Alloys

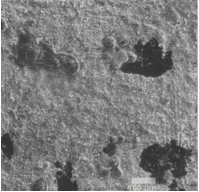

Minimox treatment of nickel alloys changes the surface chemistry of the oxide and halts flaking. The images shown below illustrate the topography of the surface oxide of treated versus untreated Nickel 600 alloy.

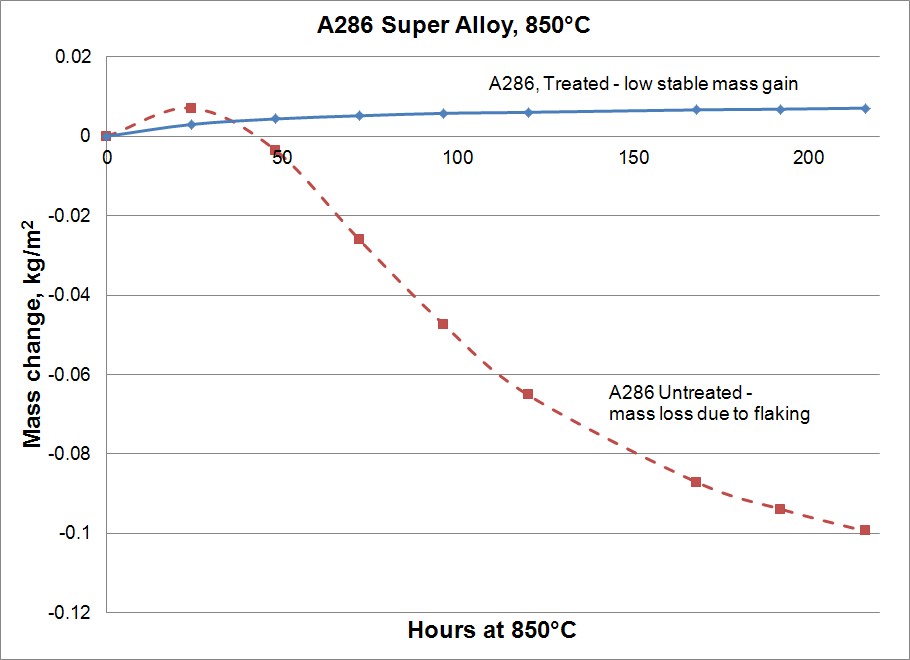

Superalloys

Coupons of A286 superalloy were heated to 850°C (1562°F) in air. According to the manufacturer, the recommended maximum continuous service temperature is 816°C (1500°F).

Aluminum, Magnesium, & Titanium Alloys

All of these alloys have grades with rare earth additions to reduce surface scaling and improve corrosion resistance. Coating with Minimox provides a cost-effective alternative to these expensive alloys.

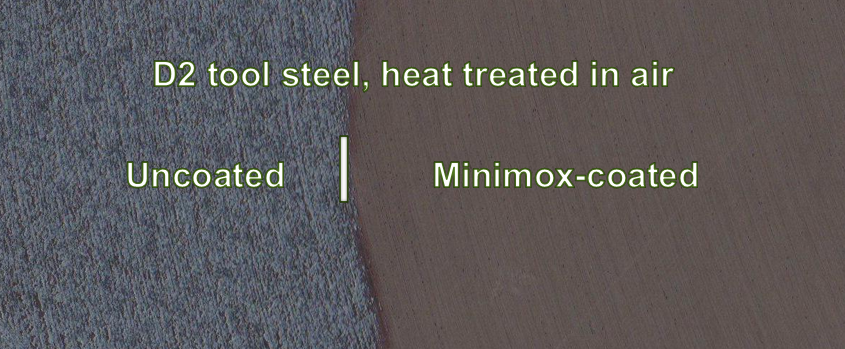

Tool Steels

Tool steels with higher levels of chromium (i.e. D2) can be successfully improved with Minimox. Research is on-going to develop a new grade of Minimox to protect other grades. Contact our office if you have specific alloy requests.