Aluminum Corrosion Resistance Improvement

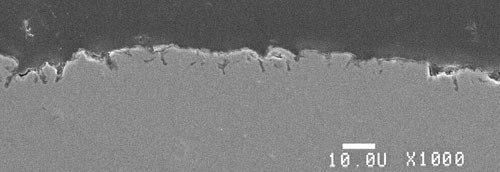

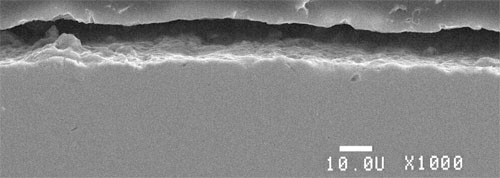

An aluminum alloy was coated with Minimox® solution and put into service in an oxidizing atmosphere. The assembly was exposed to a hot acidic atmosphere with cyclic corrosion conditions. After long term exposure, the cross sections below were obtained by an outside laboratory. The Minimox® nanocrystalline treatment demonstrated corrosion resistance under these hot, acidic conditions. The customer tested over 60 aluminum coating and alloy systems, and Minimox® solution and only one other system were deemed to have passed the test requirements.

Metal dusting

Extensive metal dusting testing has been conducted through the Materials Technology Institute. Testing was conducted at Argonne National Laboratory; Alloy 601, 600°C, 4286 hrs. Contact our office or see our Technical Bulletin for full details of the experiments.

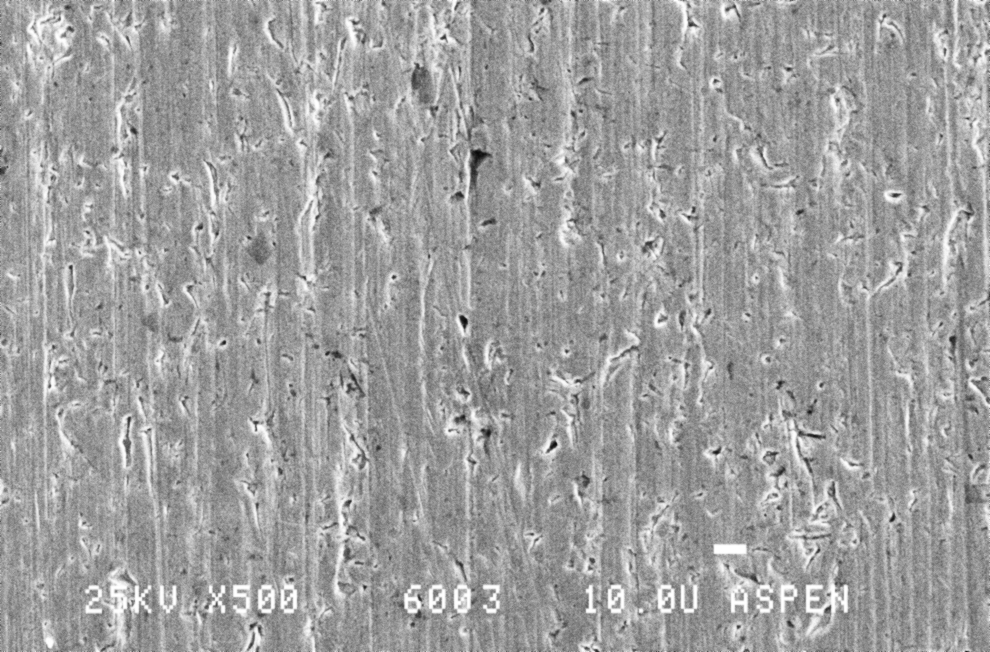

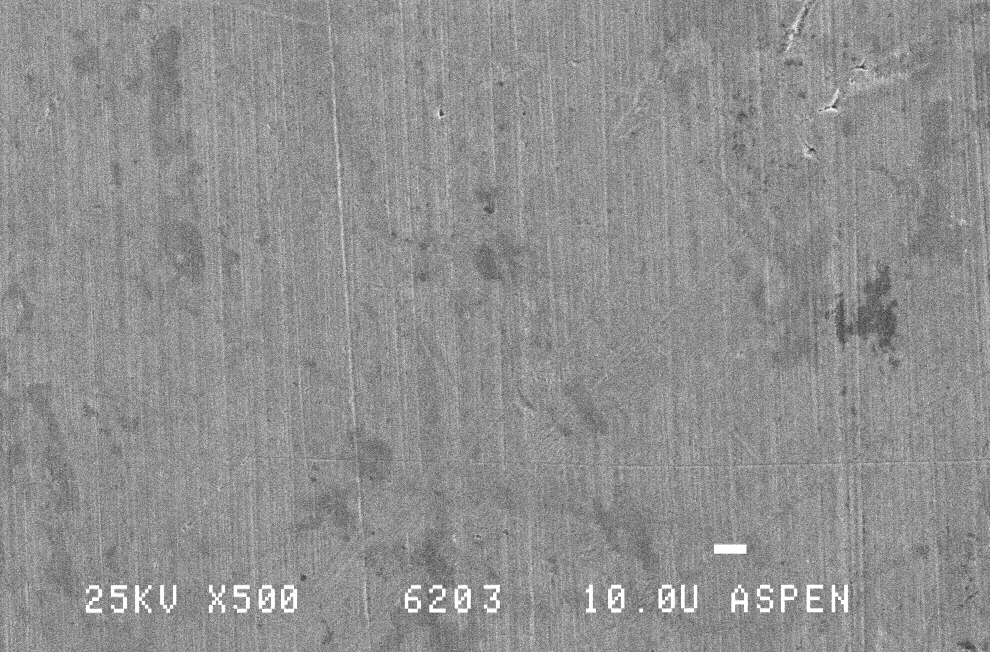

Carbon Ingress

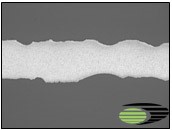

A 330 furnace belt was coated with Minimox and oxidized 850°C for 100 hours. It was then exposed to pack carburization at 593°C, 450 hours, and compared to an untreated belt. See our Technical Bulletin for details of the experiments.