Surface treatment for alloys in aggressive industrial conditions of elevated temperature and corrosion

Minimox-coated 410 stainless steel; heated in air to 850°C.

Uncoated 410 stainless steel;

heated in air to 850°C. |

Minimox® surface treatments are designed to boost alloy performance under challenging processing conditions of elevated temperature (up to 2000°F or 1100°C) and/or corrosion.

- Single component process

- Water-based

- Can be applied in the field without special equipment using spray, brush, or dip

- Can be applied inside and on complicated geometries

- No volatile hydrocarbons

- Economical (pennies/square foot)

After coating, alloys heated in air exhibit a thin, adherent & dense scale, rather than a thick, flaking oxide scale. In many instances, the thin oxide layer provides astonishing corrosion resistance.

The treatment causes the alloy to become more “self-protective” after thermal oxidation. The composition of the ultimate protective coating is primarily a function of the alloy, not the coating material.

The process is environmentally friendly and can be applied in the field. Alloy types include stainless steels, nickel alloys, superalloys, and aluminum alloys.

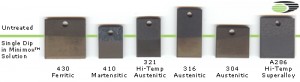

All of the above coupons were partially dipped in Minimox® solution a single time and heated to 850°C (1560°F). Protection is afforded to all of these alloys.